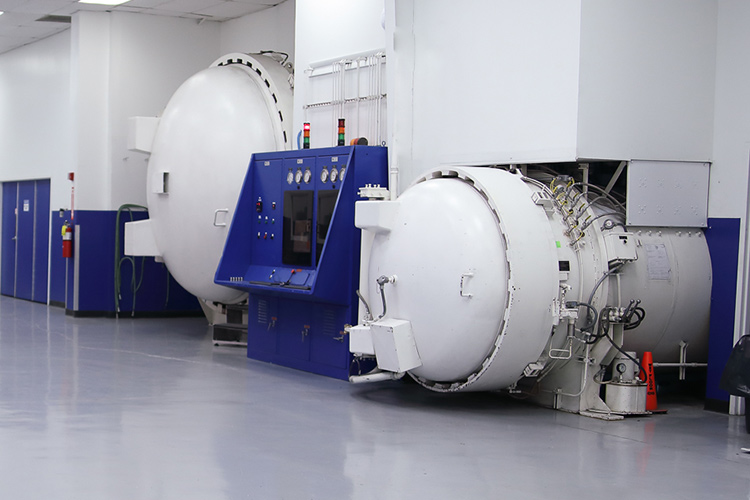

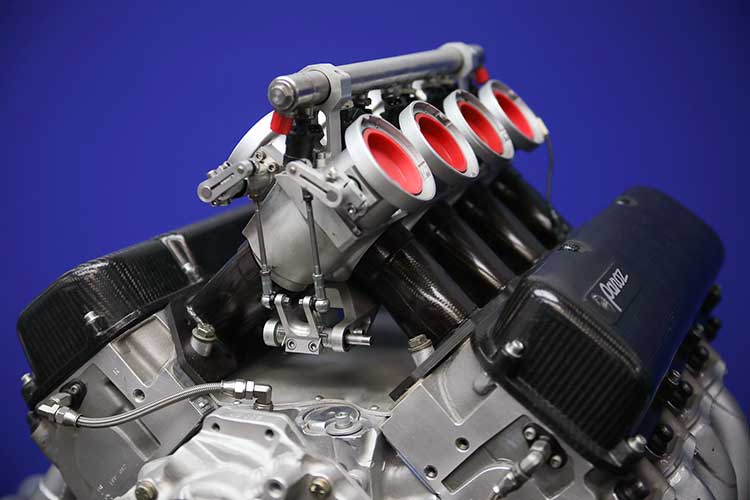

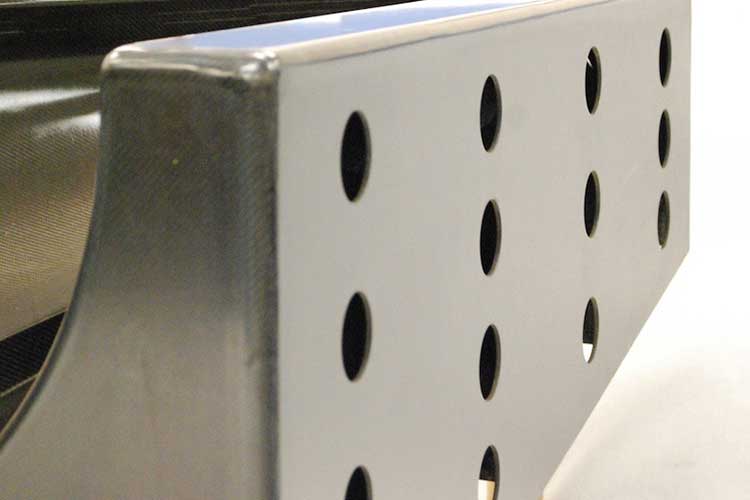

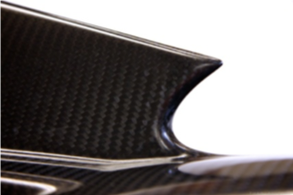

Composites is DeltaWing Manufacturing’s flagship division.

Areas of expertise include complex bonded assemblies, sandwich structures, composite tooling, and high-tolerance parts. With a variety of manufacturing techniques and processes to choose from, our composite division has success in a number of industries. We step up to challenges, and produce high-quality results. Whether prototyping a new product, or providing a complete turnkey solution including full-scale part production, DeltaWing’s composites expertise, and quality control systems will deliver the superior results you expect from an industry leader.

“[DeltaWing] clearly has the expertise to solve problems and it is immediately evident that they have the experts in place within their organization to do things the right way. Our experienced technicians and designers were very impressed with the extensive knowledge, the willingness to quickly help us find a solution to a complicated problem and we look forward to using their expertise in the future to expand our business in composite repair and manufacture.”

Delta Composites and Manufacturing

Delta Air Lines, Inc.

For more information or to talk to someone about your project, give us a call today at 706.654.2153 or email us at [email protected].